|

The first group "get together" at F38 Romford took place on the 9th January. On the menu for this working party was a thorough clean on the inside and outside and all the routine basic checks required for a vintage vehicle including tyre pressures, oil etc. A more specific job was tghe inspection and test of the appliance pump starter motor which had shown signs of "misbehaving".

Photos are copyright and courtesy of Dave Porter & Pete Cowland. Small but valuable progress continues with the last phase of the restoration of 240FLM.

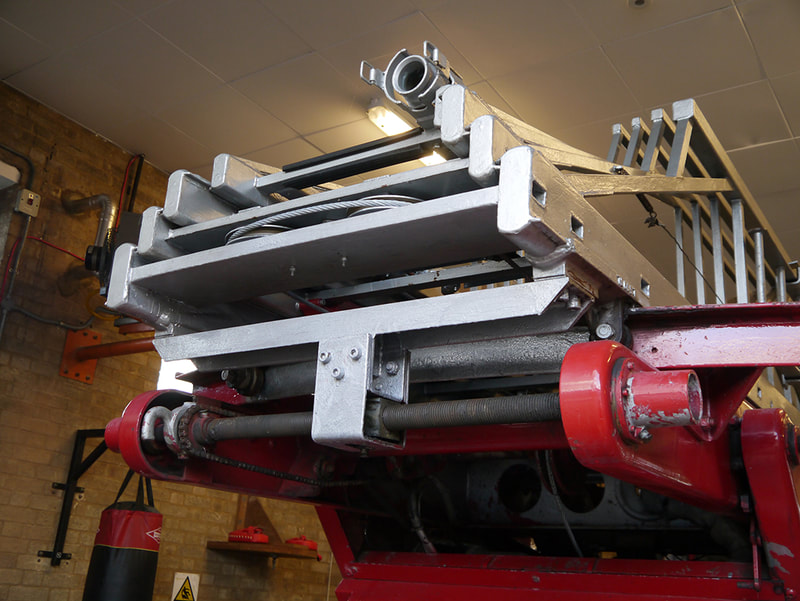

Over the last 2 months, replacement and stronger timbers have been added to the framework that supports the roof of the pump housing. This roof section holds the 4, very heavy hose ramps and it was felt that the original timbers were perhaps just not going to provide the longevity needed. At the same time and with the recent discovery of another historic photograph, we could see that the hose ramp retaining straps needed to be laid in a slightly diferent way so we took the opportunity to correct this. Work has continued with the refitting of the many and varied brackets in the lockers and it is quite a puzzle to determine "what goes where". Obviously, some brackets just simply suit a particular piece of equipment whereas others will fit a variety of items. It is just going to take time to get this right, especially as the appliance inventory evolved over its 15 years of service with equipment changes. The nearside locker is just about finished, as is the rear hose locker. The offside foot locker has all its bottom fittings in place and that just leaves the top hangers to fit, however, this is going to be a real challenge as its an awkward location for getting to and actually screwing things in, especially at our ages! Hopefully we will have that lot finished by the end of August at which point we can complete the restow. One of the hydraulic jacks continues to give us problems with unexplained oil leaks so we are working on a process of elimination as to what the cause is. Although we are still to get the vehicle logos back on ( but we do at last have the crests), the group have undertaken a number of requested event recently so work has gone on the get the vehicle prepared accordingly. The operators consul has now been fully repainted and looks wonderful and original. A range of small trims were cleaned and rapidly re attached and a niggly electronic fault rectified, again!.

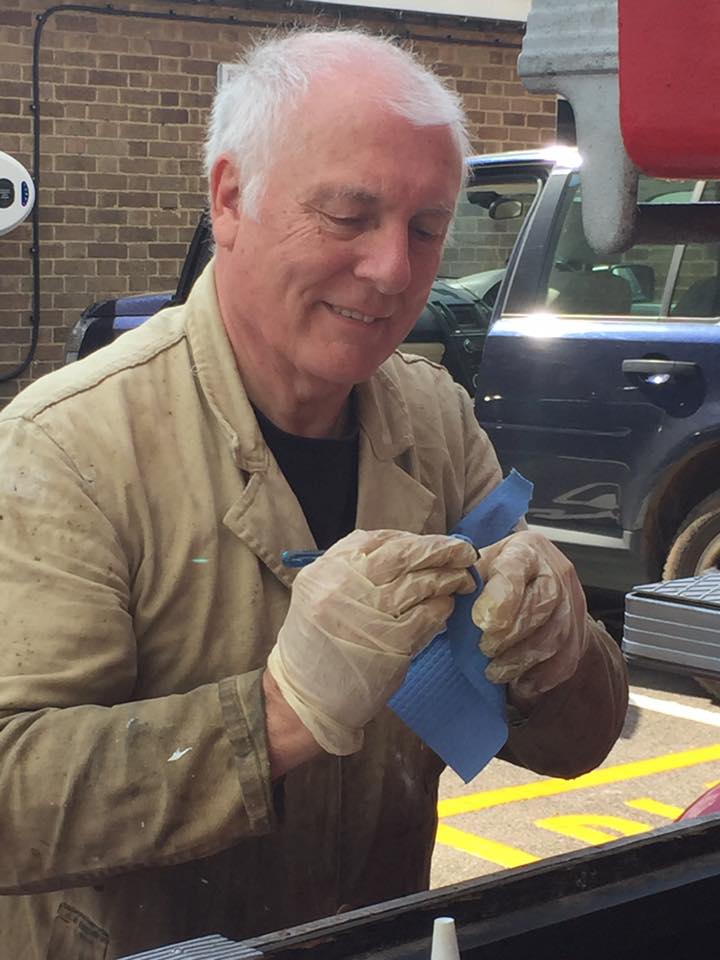

We would respectfully like to remind you that copyright to the images are strictly with the photographers, Pete Weight, Dave Porter and no unauthorised copying or reproduction is permitted. Its always the final details that take the most time and, with our project, that is very true. A series of working party days have taken place recently and real progress continues to be made. the final few elements that need painting are now either completed or in progress.

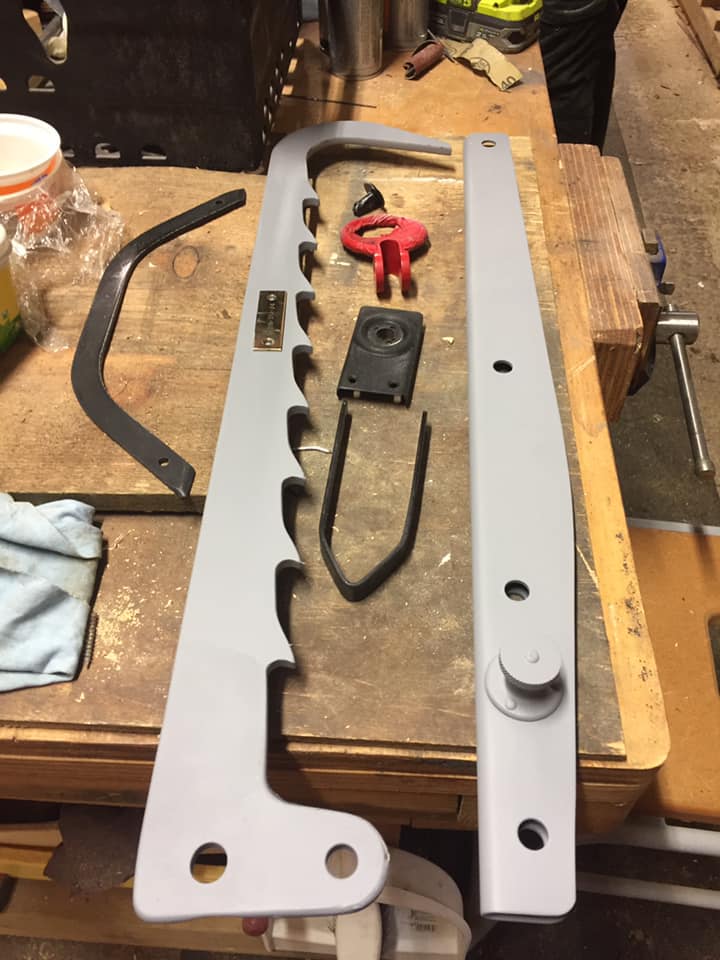

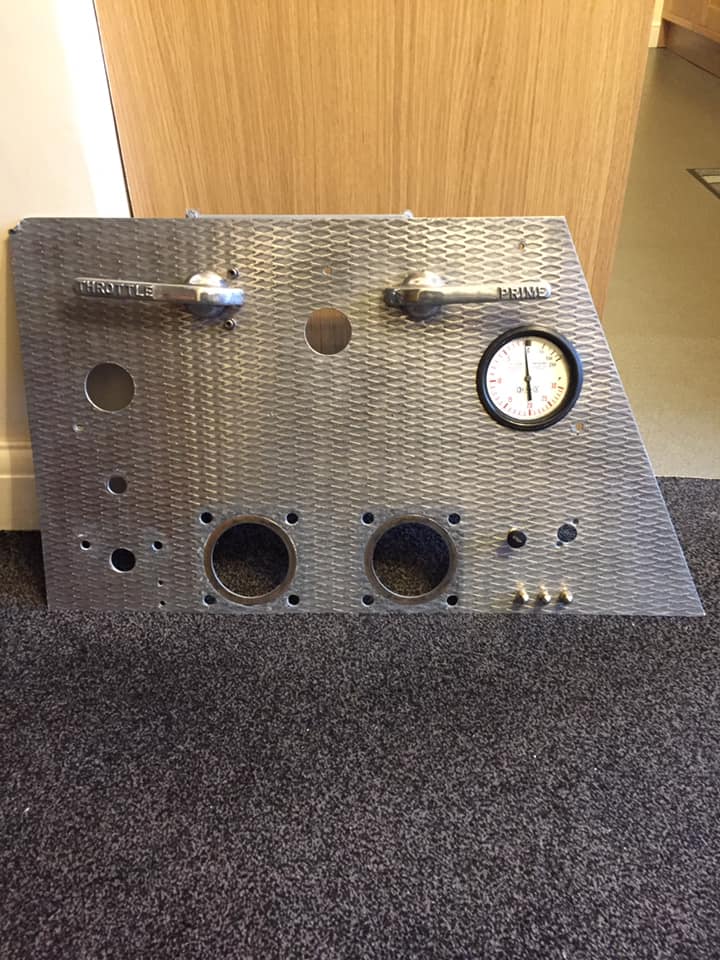

The most significant item is the operators control consul on the nearside rear of the appliance and at which the operator sits to control all aspects of the ladders when in use. This on first appearance was in overall good exterior condition, however, once the sandpaper came out, it was clear that nothing less than a full respray would be required. We hadn't really anticipated this so it has somewhat slowed our progress but it would be foolish to ignore it after getting this far. It hasn't helped that it is made of 2 different metals whcih each require a different paint appraoch so a real time taker has popped up. Most of the consul internal workings had been refurbished or replaced over the last 5 years including the communications system between the consul and head of ladder, the rotating tapes on the instruments that display all the vital information such as extension and angle of pitch have been replaced and the whole mechanism serviced. the final part is the replacement of the 2 small bulbs at the top which illuminate the panel at nightime, these are now being replaced with modern LED of the correct colour temperature to replicate the original bicycle lamp style bulbs and screw holders that are utterly rotten! The dozens of aluminium and steel trims and extrusions are still being hand cleaned and reattached all around the appliance and real dedication for this has been required as its an onerous task. Final hand painting of all the door "shuts" and door leading and trailing edges is in progress so that the whole vehicle is finally, after 30 years , all the same and correct colour. The hose ramp frame on the top of the pump housing has now been repainted to the correct colour and reinstated which just leaves the retaining straps and brackets to paint and refit. All of the above has resulted in an unexpexted delay in putting the appliance " on the run" again but we feel that by the end of next week we should be able to resume some duties. Finally, when the 6 appliances in the ordered batch were initially supplied to the Brigade in April 1964, they were given sequential fleet numbers from 237FLM getting 37TL through to 242FLM getting 42TL, later on, this was altered to TLP ( 40TLP as an example) to indicate the appliance carried an onboard pump and finally, much later in its service, the LFB applied a new set of fleet numbers throughout and 240FLM finally became TL23P. Our decisions have always been based on first issue so it was fitting that we finally reinstated its 40TL fleet number and a repainted Merryweather rear badge. We would courteously remind you that the images here are all copyright protected to Pete Weight and Dave Porter and we appreciate your support in not using them for reproduction,hire, rental or gain without our express permission. many thanks as ever. The last couple of weeks have seen continued progress with reinstatement of the dozens of trims and fittings which were removed prior to the external respray. All of them have required various levels of restoration including a good clean and polish, as you would imagine, this is a slow tedious job but well worth it when the trim goes back on the appliance.

Also, the lockers continue to be refitted with their original brackets and the equipment is now starting to find its historic home, but not without an awful lot of head scratching about " what went where". We only have our vague memories and some images we took when we originally stripped the old lockers out. However, none of those guarentee that we get it right each time so its a rather complicated jigsaw puzzle at the moment. Steady progress being made, as we used to say in the LFB! Please note that we respectfully remind you that all the images we use to illustrate our journey are copyright exclusive to the group members who capture them. No unauthorised copying, reproduction or other use is permitted. many thanks. In this case, the images were taken by Dave Porter and Pete Weight. With the pandemic starting to gently ease and restrictions being lifted, the resumption of work on 240FLM has begun. A number of working parties have taken place during February and March following the return of the appliance from the painters. The main thrust of the works have been to clean and reinstate the many metal trims, exterior fitments and body parts that needed to be removed before the preparation could be done. Cleaning the parts has been pretty laborious and with everything having to be done by hand, it has become a labour of love, rather like any restoration!.

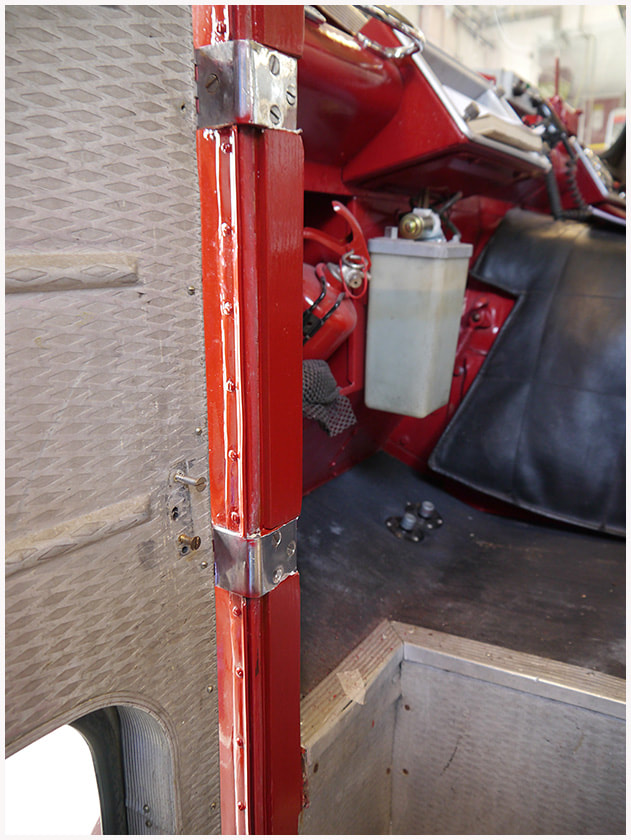

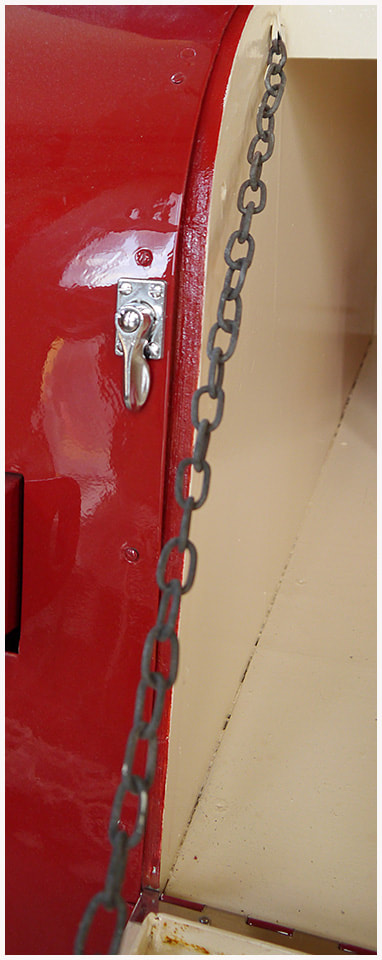

Notwithstanding that, attention has also been turned to the 3 lockers and also the door frames on the front cab. The lockers have now been brought to a full paint finish and a start has been made on refitting the numerous brackets that carry all the equipment. This has been thought provoking as we only have a set of photos that we took the day we stripped the original lockers down, and our rather vague memories of "what went where" ! Of course, some items by default will only fit in certain locations and, given that Turntable Ladders really didn't carry to much equipment, we feel that by the end of this process, we will have restored the locker layouts almost exactly as they were on original issue. The first locker item to be reinstated has been the TL Rescue/Lowering line on its cradle,harness & guide lines. This was an easy one as we all remembered where that went and with the orginal pictures, it has gone straight in on new fittings which was hand made in house. The remaining items will be fitted over the next few weeks. On the mechanical side, the starter motor has undergone an overhaul and a new drive belt sourced and fitted and the second chains to each of the foot locker doors have been fitted which now provides the full strength required to hold up the foot locker doors. As ever, one of the hydraulic jacks has developed a leak, a problem we are now very familiar with, so the fix will be a strip down and reseal where required so not an overly onerous task. Due to the continuing shortage of attendees on the working parties caused by ill health, family commitments and other issues, the progress has been slower than expected and thus the appliance will not now be back on the run until the end of April at the earliest. Photos copyright: Dave Porter, Steve Houston, Pete Weight, Colin Farrington. 240FLM. The team gathered for the first time since the return of 240FLM from the paint shop to begin the process of cleaning all the dressing pieces of aluminium and steel that had been removed before the appliance was taken in for a respray. Concurrently, a professional company attended to remove the 67 year old windscreen and fit a new rubber seal as the original was well past its usefulness and was clearly on its last legs.

Several other jobs were progressed with the electrics to the rear number plate being upgraded to modern LED and the persistent problem of the front cab doors misalignment has now been addressed. Ash fillet pieces have been crafted and the final few pieces should be fitted soon. The problem had been that the original timber under the alloy skins was no longer providing sufficient grab on the fixings for the hinges so it was proving impossible to pull the doors back into their original positions and stop the awful draughts! With the fillets installed and painted, the closures will once again look correct and hopefully the cab will be wind and water tight. The hand cleaning of all the removed alloy trims is well underway prior to the refit, however, it was felt that mechanical cleaning will be required for some as they are very tarnished so that is in hand for the next working party. With storm Eunice approaching, it was a day cut slightly short so that members could head off home before the weather deteriorated but nevertheless, a very productive day. Some pictures below suggest the quality of the finish we now have to the exterior and a full report will be published once the appliance is fully rebuilt. It would be fair to say that as a group, we are VERY pleased. Images are copyright Peter Weight. 240FLM TL preservation group. Notwithstanding the difficulties we are all experiencing with the pandemic, small teams of dedicated members have continued to make sure that 240FLM is kept roadworthy and that the restoration and mechanical repairs are undertaken.

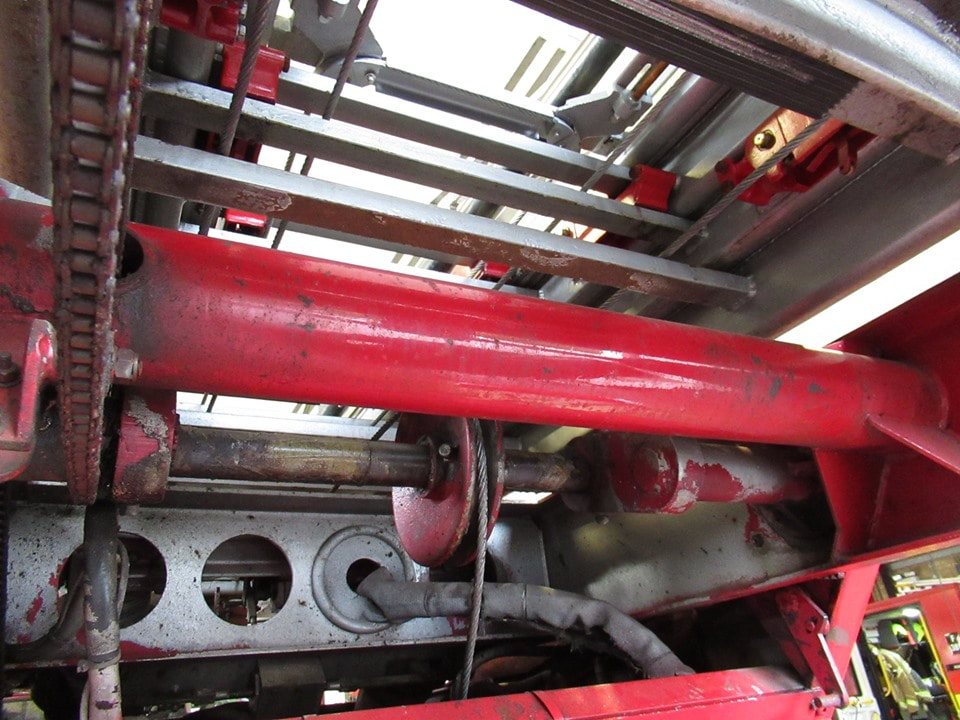

Despite the obvious limitations, some essential works have been completed and these include a main engine service, repairs to the front door frames and replacing some damaged or missing bolts from the rear jack covers. Although still somewhat limited by the pandemic and various other restrictions. A regular team from the mechanical side of the group have been busy carrying out routine maintenance and fitting replacement parts where needed. One particular issue with 240FLM has always been the tendency for the appliance to " wander" whilst in motion. This problem is not unique to this vehicle as this fleet of appliances, and probably other vehicles as well, always did have a somewhat loose feel. Last year, we were able to obtain quite a number of original parts from another vehicle that was being broken up, one of those parts was a new steering box. over a number of visits, the team managed to extract, with great difficulty, the old one and insert the replacement, which although still old, subsequently proved to be much " tighter making for a more comfortable and precise drive. Earlier on in the late summer, attention was drawn yet again to one of the 4 hydraulic jacks that are put down to support the body of the vehicle when the ladder is to be got to work. This time, the nearside rear jack was showing signs of an oil leak. The team are now well used to this and replacement seals are still available so without to much fuss, the jack was opened up and the job completed. Another area which received attention was the foot locker catches. They had begun to get a little difficult to open cleanly so a little time with a chisel and screwdriver and they once again work easily. The steering box replacement process The rear jack seal replacement. Work on the locker catches.

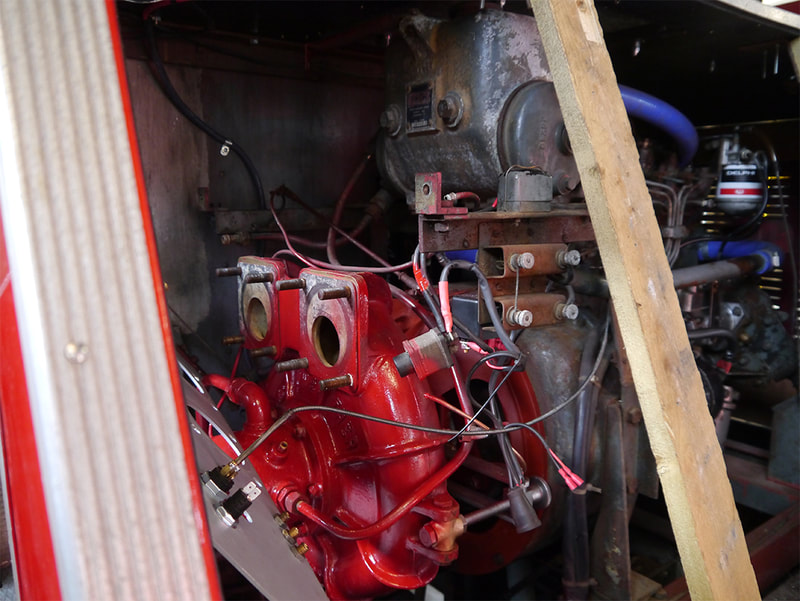

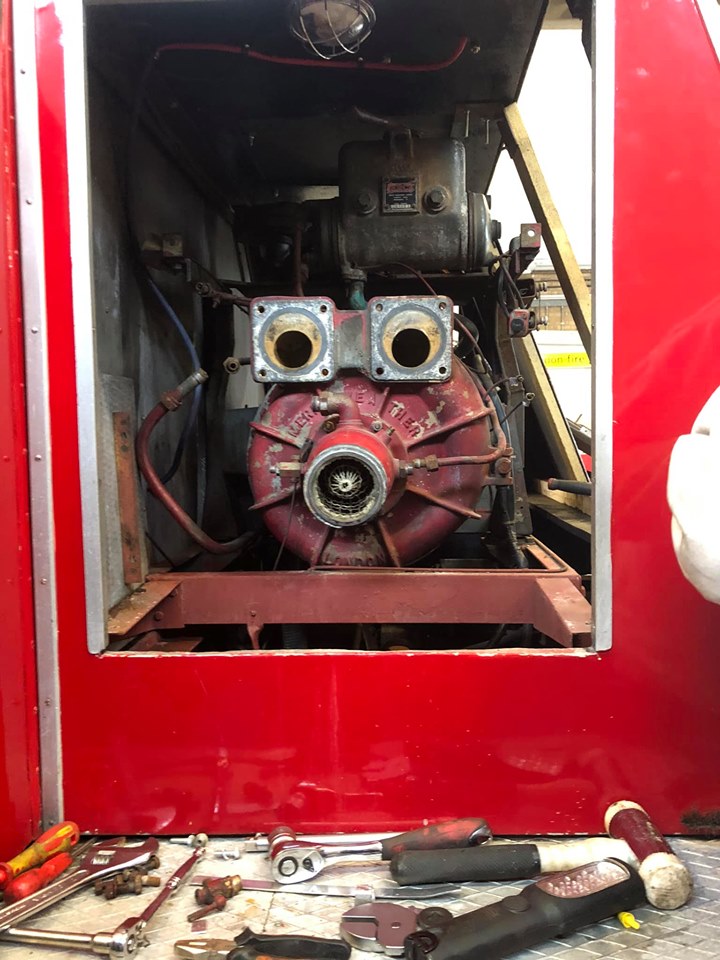

With the slow down in public appearances, the restoration team have been busy trying to resolve some of the problems that have arisen with the on board pump as well as continuing with the general maintenance and restoration.

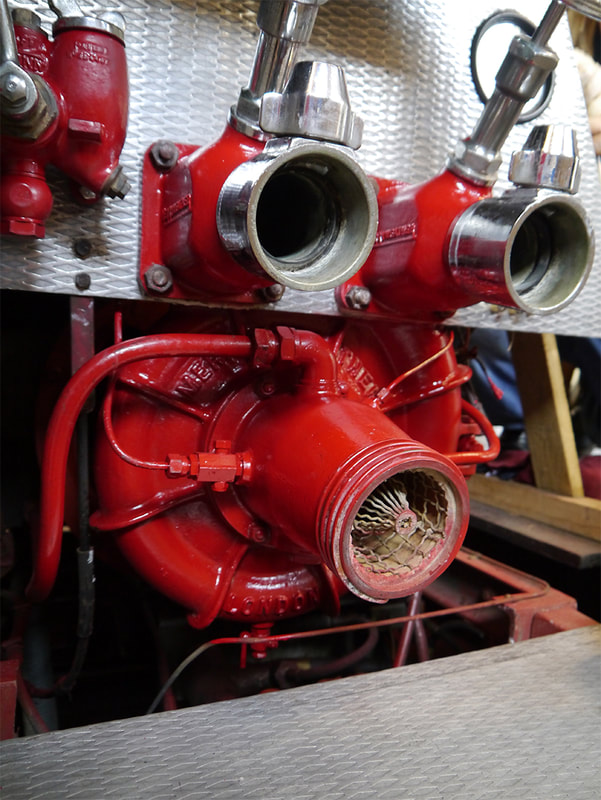

The pump has been giving us an endless series of niggly problems including water and oil leaks, failing to start consistently and therefore it was finally decided that nothing less than a full overhaul would be required to hopefully ensure that this year we can run it without fear of failure, or a good soaking! Over a period of several weeks, the pump was accessed, the control panel, deliveries, collecting head, volute and other associated fittings were removed, serviced, new bearings,seals, water pipes and clamps attached before being repainting and fitting. The restored pump control panel was also refitted and at this moment we are just waiting for a couple of the gauges to return from refurbishment and then we can do a full pressure test. The starter motor has undergone a full professional refurbishment and should provide many years of reliable service and finally, It was also decided to install a new electrical circuit to provide a separate button, relay and warning light for the glow plug operation on the pump engine. Running parallel to this, the work to complete the lockers has continued with all the final sealant and undercoat being applied and the metal locker fittings have been stripped back and powder coated ready for the final install. This now leaves the top coats of paint and flooring to install now and then we can finally restow the appliance. The rear hose locker door has been fully restored and refitted now and it looks fantastic. The Hook Ladder, formally on the run at F26 Bethnal Green, was looking rather tired and was suffering from a few splinters along the strings and a rather pronounced bend due to it being constantly hanging on the hooks on the side of the top extension of the TL. One of our members has undertaken to completely strip it down and do a full restoration. This is currently in progress and we are all looking forward to seeing it once its completed, although I don't think any of us will be climbing it again any time soon! In the front cab, ribbed flooring has been installed on one side so far. This serves 2 purposes, it makes for a cleaner appearance but also protects the floor pan which was restored 3 years ago. We will be doing the drivers side next.

October and towards the end of the month we have had to retreat into the appliance room at F38 Romford continue our work.

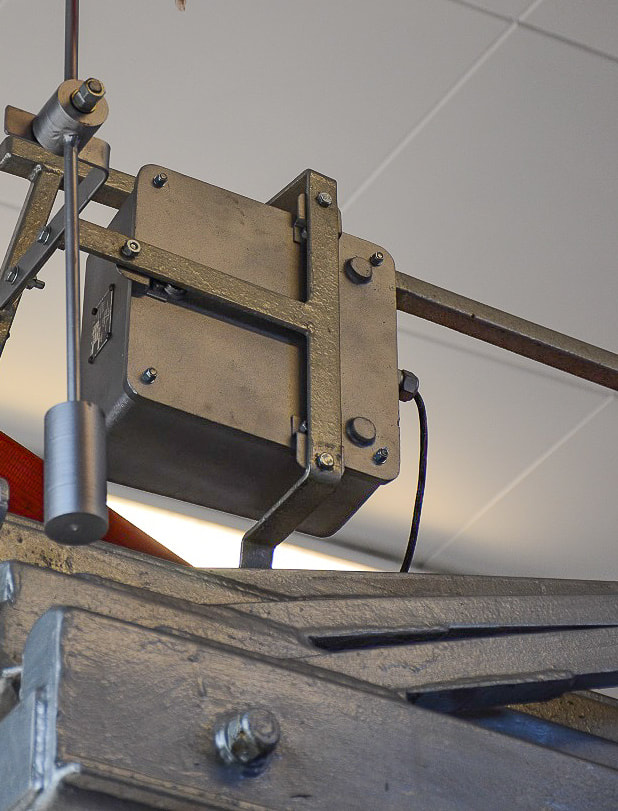

As we are guests here, we are limited to what we can reasonably undertake and we are always mindful of our surroundings and any impact we may impose on our hosts. Notwithstanding that, the restoration has continued with progress to the foot lockers, rear hose locker, communications system, and the never-ending task of fitting the new rubber treads to the rounds, of which there are many! Running concurrent to the progress has been the need to continue to carry out running repairs after our first really busy, but very enjoyable season. A priority was the appliance engine having some much needed TLC and also a replacement airline to the braking system compressor following a rather lucky discovery that the existing one was a little "leaky"!, whilst there, we installed a new compressor air filter to complete this work, the low air pressure flag now pops up and returns as it should The ongoing problem of the leaking "sparge pipe" (which is the fixed plastic pipe that sits on the offside of the top extension and delivers water to the monitor) not seating correctly in its fittings was once again addressed after a series of explosive leaks! A close inspection suggested that we had probably refitted the end connectors back to front after the restoration, and by reversing them, the pipe now sits deeper into the couplings. We are fairly confident we have solved this issue, let’s hope so as it hadn't leaked for about 40 years! Although we had thought we had solved the running and performance problems affecting the Light Pump fitted behind the crew cab, it had continued to pose us problems firstly with starting and then inconsistent running. A lot of time has been spent on this and despite our best efforts to resolve the problem with the pump installed, we have sadly had to conclude that it will have to be removed from the appliance, strip it down and have a detailed look at the issues. However, We will need to programme this in and find a more suitable venue for this job as it will require a “Hi Ab” lift to get it off the chassis and also require a little frame cutting to get it out. The painting of the lockers has at last been started and all of them are now at the undercoat stage. The front section of the nearside locker has had a second inner floor added and drain holes have been drilled in the offside and nearside lockers as water was collecting in them. Once the final painting has been concluded, we will be fitting period correct linoleum to the bottoms of the lockers to complete the preservation and provide some longevity to the work. The rear hose locker door was looking rather sad on the inside so one of the group members set about cleaning back years of paint, a painstaking job but with the paint off, the door has been removed for repainting offsite. While we have it off, a replacement hinge was sourced as the original of 50 years plus was not looking very sound as it was made of brass with a chrome finish. The chrome had lone gone though so we have had to buy a stainless-steel version sadly as original brass are no longer available. Fortunately, as its almost entirely hidden, we are satisfied that this will not impact on the appearance. The operator control position has also been having some attention as we had noticed that the extension dial had stopped working. It was found that the tape had parted from the spool and, as it is another one of those 50 year old items, we have sourced and fitted a new replacement and all is now working correctly again. The communications system between the consul and head of the main ladder is now finally working after a full and complex restoration. We had been inching towards getting this working for about 4 years but it was never really at the top of the“ to do” list. Finally now though, with a replacement amplifier fitted in the consul, it has sprung into life, and, although this is a tiny non visible part of the overall project, it is very significant as it means we have full communications between the ground and head of the ladder which serves a couple of purposes.The first is the basic historic one of it being there and working, then, a more modern Health & Safety element as from time to time we do have firefighters up there who have never been up a TL before so this is a very important function and device for us. The window screen wipers on 240FLM have continued to plague us with inconsistent working and swing but this is not surprising really being 55 years old. We have had to have rubbers specially made and it has proved impossible to locate new replacement arms of the correct shape and size. We have had new arms made, rubbers cut and fitted and finally all the new elements were refitted and now appear to provide a decent “wipe” and clean so the driver can actually see where we are heading! Although we have only had 4 working parties during October, they have been well attended which meant that we have been able to make excellent progress and we continue to be very grateful to the LFB for allowing us the privilege of residing within an operational station, exactly as 240FLM once did. September has seen a number of smaller working parties take place. The initial session was to review and address the mechanical issues that the appliance had suffered over the summer show season, particularly the final show at Odiham in August where 240FLM just refused to participate fully in the show display of 3 turntable ladders which was very disappointing for us.

Inspection of the ladder traverse sensor/activator revealed that it had in fact just dried up through lack of lubrication and jammed. This had prevented 240 from being able to rotate during the show and it ultimately was an easy fix with the traditional wiggle and a large dose of WD40! We are constantly learning about this old beauty as none of us had ever been mechanics before, just LFB firemen who used the appliances. This therefore is a whole new learning curve for us but by the time we have finished the whole restoration we should be in an enviable position of being drivers, operators and MRV’S! ( Mobile Repair vehicle). Attention then turned to continuing the re installing of the communications system between the operator’s consul and the head of the ladder. The whole top speaker/microphone box had been removed for refurbishment 18 months ago so we knew that was good, the entire length of cable had also been replaced so that was good. However, the one thing we had not yet got around to was the operator consul assembly. After much tweaking and scraping of knuckles, we managed to get the alert horn button working and the 2 parts of the system communicating, we couldn’t get any speech through it though, again, more head scratching and we ultimately discovered that the consul amplifier was defective, well after 50 years its not done to bad!, so a replacement has been ordered. The plastic sparge pipe fitted to the top extension and leading up to the to the monitor short hose length had developed a leak of quite epic proportions so it had not been used for the last 2 shows. The sparge pipe was removed for inspection and it was found that the top coupling threads had worn away so new fittings were ordered and have now been fitted and tested to 8 bar pressure. All is now watertight again and the monitor works correctly. The combined efforts of several of the group resulted in the long-awaited fitting of the brackets, straps and wheel chocks to the original positions on the side running boards. The frames were hand made in house, the straps likewise and the original Merryweather chocks given a full repaint. The whole lot came together beautifully and they fitted perfectly back into the original screw holes first drilled 55 years ago. This almost completes the exterior in appearance although we know that we still have bodywork refurbishment to address during the winter. In the crew cab, an original 5 metre radio main cable, speaker connector and vintage P clips had been sourced and our newly recruited and much valued auto electrician has kindly reinstated all of these elements to complete the wholly authentic radio setup we ran with from 1966 to 1981 when 240FLM was decommissioned. The dashboard area is now complete and really takes us all back to the days that we remember and enjoyed so much. As we now have the on-board sound system playing original radio traffic it completely brings the cab alive and if you close your eyes just for a moment, you really are transported back in time. Brilliant! The foot lockers have been emptied to allow them to dry prior to the preparation and repainting back to the original colour of “County Cream” to match the cab interior. Again, this will be a winter project but once done the whole stock of original gear and equipment can finally be brought out of the various garages and stores at the homes of group members and restowed. And finally, 240FLM was given a thorough clean and polish which she was desperately in need of. Although the show season has almost finished, 240FLM will be making an appearance at the forthcoming LFB Fire Station open day at Hornchurch Fire Station, which is located at 42 North Street Hornchurch. RM11 1SH, on Sunday 22nd September 2019, opening at 12.00pm. Why not pop along and have a look inside this iconic appliance, say hello to the crew and participate in another interesting fun filled day. As we move into the Autumn, the group would like to extend it’s thanks and gratitude to all those readers and followers who have supported our project either with words, deeds or donations of unwanted equipment and uniforms. All of this is greatly valued, and, where we do not actually need the items, we try wherever possible to support other projects with items that they might need so everything eventually finds its way back to its correct home on a restored fire appliance. Work has continued both at Romford and various individual homes to push forward with getting 240FLM ready for this years events.

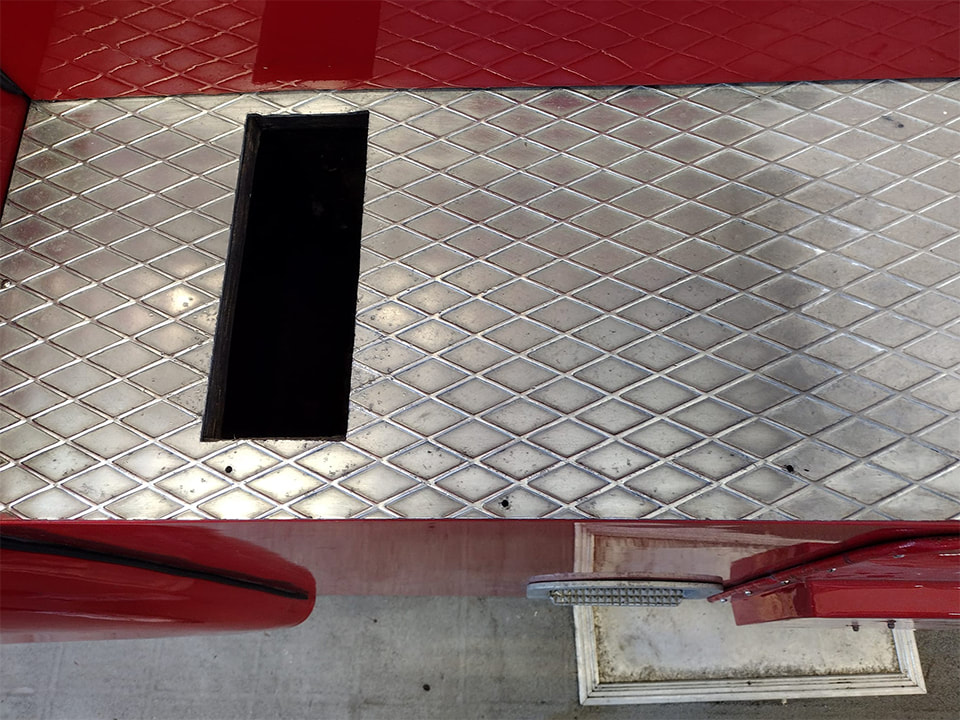

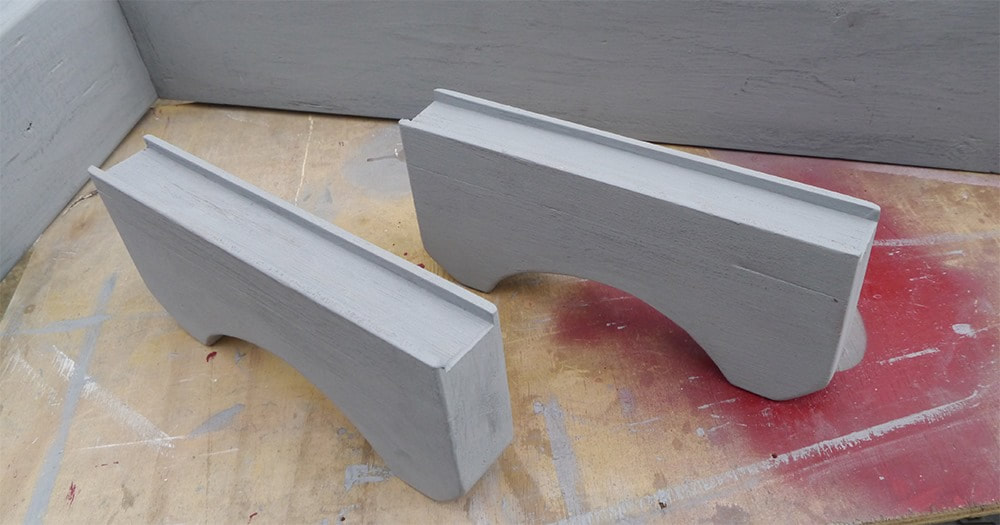

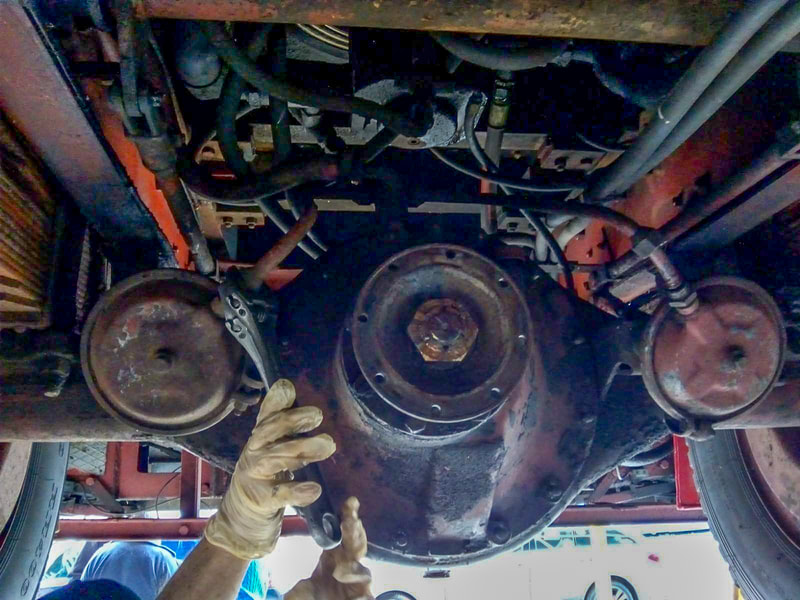

Both Pete Weight, Graham Pearce and Trevor Barnwell have all been busy working on different projects and these should all be completed for the end of June. Trevor had been working on a sound system through which to play some original radio traffic commensurate with the service period of the appliance. We had considered 2 options to do this: A wholly digital system utilising a Bluetooth mini speaker and an Ipod, or, a portable CD player and played through the original radio speaker. It was finally decided to follow the CD player route and accordingly, a "new old stock" Goodmans CD player was located for £10, a 24 volt to 6 volt inverter and a miniature Mono amplifier. One of our new "recruits" John Lewis set about the task of connecting everything up and hey presto, It worked! The whole arrangement has been installed behind the OIC seat out of general sight. Whilst moving this project forward, it was also considered sensible to install a couple of USB ports at usable locations to cope with the modern requirements of the crew and we now have one in the OIC glove box on the dashboard and one in the rear crew cab. This has brought a tremendous sense of realism to the project, especially when the vehicle is static on events as the real life dramas that occurred so long ago are still so vivid coming out of the original speaker. Attention has also been focussed on the door handles and catches with another new recruit, Martin Baker, getting on to them. most are now restored to full working order and the door straps are next in line for attention. A noticeable issue was identified on several of our recent events, events where kids climb into the rear crew cab. We do have any suitable step system for getting them in safely and exiting the other side so thoughts turned to sourcing a pair of appropriate steps. When we originally purchased 240FLM, she came with a single set of steps, fortunately, we had photographed them before they " disappeared" so had a visual template to work to. Graham Pearce offered to undertake this project and today we have a lovely pair of tailor made, sturdy, dedicated steps almost ready to use this summer,final painting takes place this week. Also offsite, Pete Weight had been busy making the hose ramp retaining parts that all sit on the roof of the pump bay. Nick Gunn had created the 3 flat bearers that the 4 ramps sit on but we still needed the wooden surround so Pete made this up and painted everything and while the brushes were out, also final painted the 2 hand made extinguisher brackets that sit in the rear cab. Towards the end of May, all the parts that had been made offsite were brought to Romford and over a couple of days were installed. The sound system is now fully integrated, the extinguisher brackets, complete with their original leather straps fitted and the 2 original extinguishers we had sourced fitted into place. The hose ramp securing system has been faithfully reproduced complete with original leather straps and the 4 ramps fitted. Colin Farrington has continued to make progress on the mechanical side resolving several niggly little leaks and issues and Steve Houston and Dave Porter have had periods cleaning the very dirty checker plate decking. Dave has also been busy refitting the dozens of fiddly metal securing plates that retain the rubber treads on the rounds, an extremely tedious and knee jarring job! One step forward and another back! A well known saying and one which has definitely applied this month. At the start of the month on April 6th, the team set with 240FLM for the overdue replacement of the rear differential oil seals which had been delayed from earlier in the year due to a " fail to start". However, this time no such problems and the small team of group members made their way to a local HGV repair facility kindly loaned out to us for this task. The appliance was carefully driven onto the hydraulic lift and the team set about the task in hand. Everything went as planned and the seal was replaced fairly simply and without any great issue. However, it was at the point of concluding the days work that the problems started. The starter motor refused to engage and there was a distinct smell of burning rubber or similar and so it was concluded that the only thing to do was to return the appliance back to the hydraulic lift and have a look. On investigation it was found that the starter motor had indeed failed and there also appeared top be a fuel system issue. By now it was mid afternoon so the decision was made to call for a heavy recovery lift back to our base at Romford, it had been a long day with the driver finally parking the appliance back in the station at about 8.00pm.

During the week that followed, the starter motor was stripped and a full overhaul conducted. Fortunately, within the group we have the skills to do this work so it didn't take long for the motor to be returned and refitted. With the fuel system bled, the appliance burst back into life and hopefully the starter motor will provide another 50 years of service. Later in the month we held a busy working party during which the hand bell, which had required a new strap was refitted. Some woodwork around the OIC door had been stripped back and this was primed ready for coating up. The hose ramp retaining frame that sits behind the cab, but had been mostly missing when we obtained 240FLM, had been constructed offsite and this was trial fitted and the fixing holes drilled out. It will now be brought to a full paint finish and the 3 base runners that the ramps sit on will be finished. The 12mm radio cable was trial fitted and reaches from the radio on the dashboard to the rear seat area under which the transceiver will sit but some alterations are required to the connector to get it to fit, this is in hand and once installed, the cable will complement the "original" appearance as it is in fact a period item found by chance for £5 plus postage on an internet auction website. Offsite, 2 new "original" extinguisher brackets had been made for the Foam and Water Stored Pressure extinguishers in the back cab, These had been routed out to accept the straps on the back and are now ready for final painting, strap attachment and fitting. On the same day, attention was given by some of the team to the problem with the communications system that runs between the operators consul at the bottom and the speaker box at the head of the ladder. Although the whole system is now installed, the cable should run smoothly when the ladder is extending or housing, To assist the functionality of the cable, there is a twin wheel runner set that sits in a channel above the cable, It was noticed that the twin wheels were sticking at various points and after much investigation it was discovered that the trough that they sit in was heavily congealed with old muck and rubbish. This has now been fully cleaned out and should allow the system to perform correctly. The on-board pump had been presenting us with problems and had recently failed to start. After much searching and testing, it was established that the fuel pump had become defective so it was removed, thoroughly overhauled by group member Mike Cotton and refitted. A little tweaking and checking and once again the pump has fired back into life and runs beautifully. It is our intention to have the appliance fully functioning in all aspects so this is a significant step towards that goal.

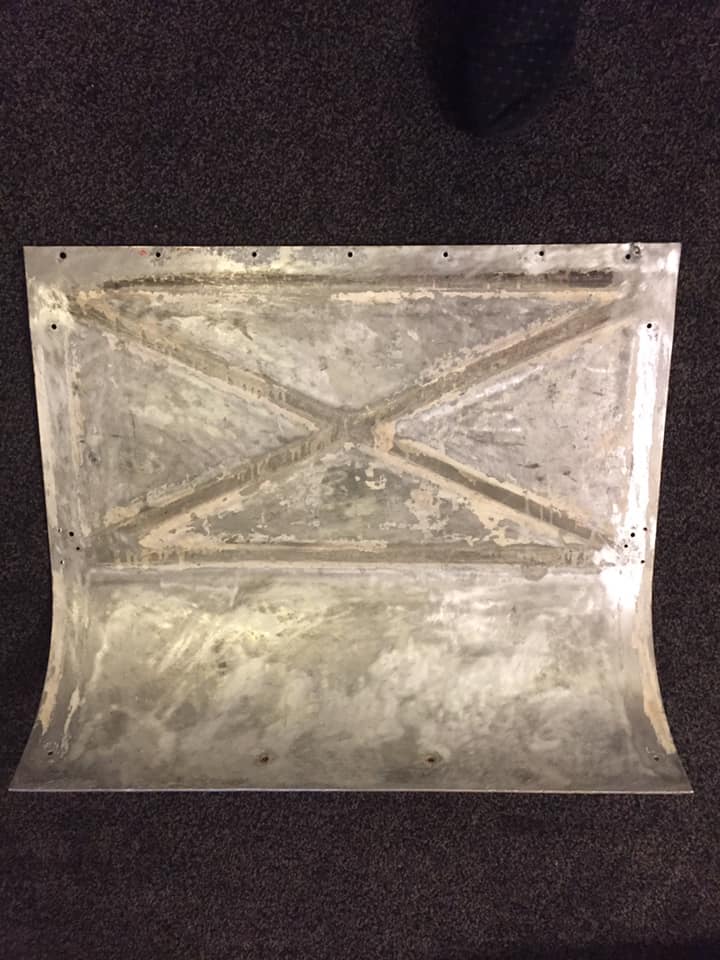

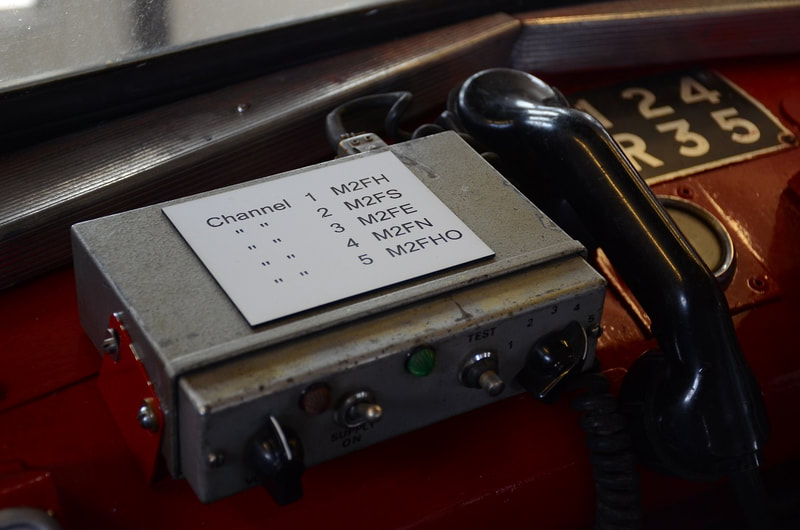

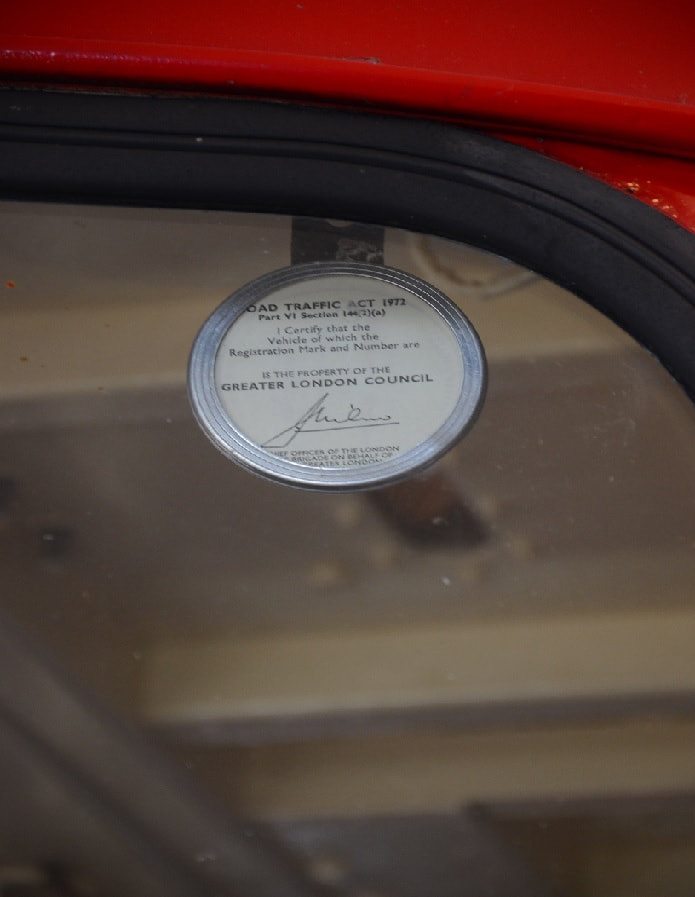

To complement the mechanical repairs, the pump deliveries and collecting head have had their ( non original) blank caps cleaned and reconnected via new galvanised chain. Unfortunately, the original chain remnants, (of which there was 3 different sizes) is no longer available so the closest match to that seen in the pre delivery pictures we have was purchased and used. The driver’s dashboard gauge cluster had for a long time been in need of complete overhaul. Some of the more vital gauges in fact didn’t function at all so after much thought, this task was handed to professionals and the results are fantastic. A new set of cables were made and now that it is connected and reinstated, it completely finishes the repainted cab and dashboard. Also fitted in the cab was a modern 2KG dry powder extinguisher. It had been considered a sensible precaution in case a member of the public approached us in an emergency, or, we needed it for ourselves!! The exterior has continued to have finishing items added. The cable reel to supply the Francis searchlight has been refitted to the roof of the pump bay having been fully restored by Graham Pearce. It is likely we will be replacing the 50 year cable though as it looks rather unsafe! The original windscreen washer system, including the plastic reservoir in the OIC footwell looked quite serviceable, however, it became clear that it wasn't pumping so a replacement pump has been sourced and installed and the system is once again working correctly.The Raydyot hand lamp for the OIC had developed a sever crack in the swivel joint since it was installed last month. Fortunately, one of our group members is a dab hand with brazing equipment so out it came and has been repaired and now sits back in its position, this now needs wiring up. The Original radio channel plaque was in a bad visual state and, as this is on show, it was concluded that a new one was probably more suitable.This has been made and now sits back on top of the radio control box on the dashboard and reflects the early period in the Brigades radio history. The " Licence" holder is now in place complete with the Joe Milner period certificate of ownership, we can however switch this to Mr Leete's period in tenure if we desire as we have one of those as well. The drivers side floor has had its coat of black metal paint and this now means we can go ahead and install the rubber matting. Attention will now turn to the 3 lockers on the outside. There are 2 foot lockers and a rear hose locker. All 3 were hand made by the group and the original skins then laid over. All 3 are currently still in the paint primer stage and it is our intention to get all 3 fully repainted and then refitted with the myriad of brackets, hooks and wooden formers that we removed some 3 ½ years ago. Once completed, this will allow us to restow the appliance with all the original LFB gear and equipment we have been able to collect since November 2015 and be one giant step closer to being able to proclaim 240FLM as “ On the run”. Finally, a start has been made by Dave Porter on cleaning the original checkerplate decking which has been long overdue, initial impressions are that it will come up a treat for the summer. February has seen significant steps forward in our winter maintenance and improvement programme.

Works by Trevor and Martyn to the onboard pump have resulted in the fuel pump being removed and dispatched for a much needed overhaul. It had become clear that this was the cause of the pump not firing when the start button was pushed. The dashboard has been completely removed and sent away for refurbishment as several of the gauges were not working and the surround needed painting. Colin has started the first phase of the reattaching of the communications cable, between the head of the ladder and the operator consul. The cable is now loosely attached along its full length and connected to the refitted operator speaker and microphone box which is fitted at the head of the ladder. However, 3 specialist springs are required to keep the tension on the cable so these are being made " in house". Once made the whole system can finally be permanently attached and tested. 2 "new old stock" headlamps have been sourced and fitted by John Lewis as the silvering on the originals had started to fail. In the crew cab, the radio, handset and speaker have now been fitted and immediately this has brought the cab back to life. The intention now is to install a small "bluetooth" system, played through the original speaker, to run original radio soundtracks appropriate to the service period. Also, in the cab (and pump bay) the replacement interior lights have been installed and are fully functioning. Graham has finished the painting on the remaining ladder section at the foot of the main ladder and also given the steering column a much needed lick of paint, Trevor has also managed to get the " High Wind warning" pennant bracket at the head of the top extension painted in silver which is far better than the rust colour we had been looking at! The foot mount for the Francis searchlight is now back on the roof ready for the light itself although this is currently being rewired and the hunt is on for an original " Niphan" bullet connector to complete the period look. Finally, when the original interior cab lights, and the pump bay light, were removed for restoration, it quickly became apparent that they were beyond redemption!. It was fortunate that the identical " cage" lamps are still produced so with 3 new ones on site they were immediately fitted and connected, all 3 work perfectly! Attention was focused on the on-board Light Portable Pump or " Donkey Pump" as its sometimes known *( it supplies high pressure water to the monitor at the head of the ladder when utilising the appliance as a water tower for large fires). A couple of years ago, we gave it a limited refurbishment with new filters, exhaust and hoses and it had in fact run well but we didnt pump any water or put it under great strain. So when we came to fire it up in the new year, it steadfastly refused to start. A thorough visual inspection of the ignition system showed that we had a good spark and therefore a good electrical system so a strip out of the fuel system followed. This revealed that the fuel pump had failed so this has been removed and sent for repair. We have just been informed that the pump needed a thoroughly good clean and service and it has now been bench tested and produces the correct jets of fuel so it now just needs a final seal change and it can be refitted. Our thanks go to group members,Dave Porter, Trevor Barnwell and Mike Cotton for resolving this problem. The hand bell over the Officer In Charge's seat has been removed to allow for a replacement leather strap to be fitted as the original one disintegrated this summer. The complete driver instrument cluster ( dashboard) has been removed for overhaul and refurbishment as some of the gauges just didn't work, this should take several weeks to be completed so until then, 240FLM must remain static. Running alongside the mechanical repairs and servicing, other group members had set about reinstating several of the new, or restored, original accessories inside the cab and on the exterior. One very notable item to be restored has been the 8 day mechanical clock located centrally above the windscreen. This had been gifted to the group and it has fitted perfectly to the existing back plate and works beautifully. An original, gifted, address/searchlight for the Officer In Charge was refitted. However, sadly a crack has appeared in the swivel mount so this will need to be brazed at some stage. Notwithstanding this, the period wiring can now be run to make the lamp functional. After many weeks of deliberation, the final position of the radio receiver and handset were decided. Months of research had failed to provide any firm evidence of the fitting positions and no photographic evidence could be found. Discussions were held with retired members of the LFB Radio Workshops team and they confirmed that radios, speakers and handsets were in fact not fitted in identical positions and it very much depended on the appliance and fitter on the day. As no absolute certainty could be found or traced for the exact location, our joint collective memories decided on a later, known location, and the holes drilled accordingly. The new radio mount bracket will now be painted and installed on the next visit. The radio speaker will sit just to the left of the driver on the central divider, exactly as seen in several period appliance images. The handset will sit high up on the dashboard between the driver and OIC. Once all the 3 elements are installed, period wiring will be run to finish the project and it is anticipated that at some stage, we will install a Bluetooth speaker and player in the cab and have period appropriate recordings of radio traffic playing at events. Measurements have been taken for the 3 wooden bearers that sit on the LPP pump housing behind the cab to accommodate the 2 hose ramps.These are now in construction and period leather straps have been sourced and are ready to fit once the wooden bearers are made. The mechanical team gathered at Romford today with the intention of changing the engine oil & filters and a provisional look at the the next task of changing the gearbox oil. Meanwhile others had arrived to start the installation of some of the fittings and accesories that will start to make 240FLM look original again.

With the necessary safety options in place, the drain plug was opened and a rather unpleasant looking volume of old engine oil appeared. No one actually knows when it was last changed as we hadn't done this since we purchased her, however, it quickly became apparent that this was a wise decision. The rest of the day was spent inspecting the general access and state of the mechanics in preparation for the forthcoming season. Meanwhile, the other lads were busy installing the new roof aerial and running the cable from it back towards the radio pack which, if we can locate one, will be sited in its original position under the offside rear crew seat. A fully restored original CTC ( Carbon Tetra Chloride) extinguisher and bracket were fitted in the correct location behind the drivers seat. 2 of the newly re-chromed grab handles were refitted in the front cab, much to everyone's relief, the hand bell was removed to allow for the replacement of the leather strap which had broken during one of our event days and the original remnants of the 4 chains that retain the female blank caps were removed to enable us to try and source replacements. All in and excellent days effort before christmas. During the course of November, a number of working parties have taken place. The purpose was initially to seek to remove the differential so that a troublesome oil leak could be repaired. However, on the chosen day, an electrical issue meant that we were unable to relocate the appliance from Romford to a pre-agreed location nearby where we could have use of HGV ramps.

Undaunted, the team set about the next task of dealing with the removal of the rear brakes to assess the condition of the linings and other mechanical parts. Over a period of 4 weeks, the small team, working outside in all weathers, removed both sides, and sets, of wheels, brake drums, hubs and seals. A thorough inspection revealed that the hub seals were failing and the brake linings were heavily contaminated so the decision was made to replace all these parts. The brake shoes were relined and new seals installed. This was an onerous task, made all the more difficult as most of the team are of a more mature age and the weather was not always very kind. However, a very determined and small group of members, led by Colin Farrington and Trevor Barnwell supported by Dave Porter, Steve Houston, Steve Lomas and other supporters got the job done. 2 working parties were undertaken during August. On Saturday 18th, Pete started the final push towards getting the front of the cab area painted whilst Graham Pearce set about the final part of restoring the “Fly ladder” brackets with new copper washers and leather inserts. Before setting about the actual cab, it was decided to try and clean up the aluminum trims around the windscreen and dashboard areas. This was no easy task as they hadn’t been cleaned in probably 30 years, are a difficult shape and area to get at and Pete had no real experience of the best method to use! After much head scratching and trying different techniques and materials, a plastic based rotary drill attachment with some metal polish, accompanied by occasional wire brushing, produced an acceptable finish. Once this and the full masking up of the areas were done, all surfaces were cleaned thoroughly and finally the paint could go on. The dashboard area and the engine top cover had 1 top coat before time ran out, but the signs were promising for a good finish. Graham meanwhile had made good progress but was prevented from finishing as he ran out of copper rivets. The following week, Saturday 25th, Pete & Graham were back at Romford for a re run but this time it was decided that every effort should be made to get both jobs fully finished in advance of the next event for 240 which was going to happen on the following Sunday.

Once again, the front seats came out, the cab was stripped of all the small parts, had a thorough flatting down, clean and finally the masking up done and then the paint could go on. Once masked up, we were about to start the spraying of the area behind the seats when we realised that like last week, we should sensibly try to clean down the brightwork and trims abutting the paint area. Last week was a real trauma trying different systems to clean the alloy so this time, a more pragmatic view was adopted and Pete set about the central divider top panel with a small amount of extra fine rubbing compound and a superfine sanding soft pad. Eureka!!! It has come up a treat with almost no effort. This will now be finished off next time with a quick clean with metal polish to be sure of removing the remaining paint residue from previous efforts of others. The back panels and engine side panels had their first coat, the front dashboard area and engine cover, which had previously had 1 coat got masked up and then had their 2nd coat, and finally back to the rear panels and engine side panels for coat number 2 and the job, was done with ½ can of paint left out of the 6 x 400ml tins we started with. It is really pleasing to see 240FLM with her correct colour reinstated, hopefully next year we will be in a position to do the same to the outside. Work continued on the preparation and priming of the front cab interior. With the seats removed, it was possible to get in the tight corners to apply the spray primer. A small repair was done to the underside of the engine cover and whilst it was off, it was thoroughly cleaned of 50 years of grime!

The next step will be a final flattening and then the top coats can be applied. A little more progress this weekend!

The dashboard,surrounding framework and the back panel behind the OIC seat has now been partially spray primed/undercoated. Being amateurs, we are having to find our way through each job both with regard to the work and the materials. Therefore, it was decided to just get one " rattle can" to see how far that would go. With the masking up and final wipe down complete, a small fibreglass patch repair was sanded back,the OIC seat removed and spraying commenced. The nearside footwell was given its last coat of "Hammerite" to make the final seal to the pan before the floor covering is fitted. The rear seat cushions and back pad were reinstated and that element of the work can now be signed off. Not the busiest day but good progress continues to be made. A very happy new year to all our friends and followers, we hope you had a most enjoyable seasonal break.

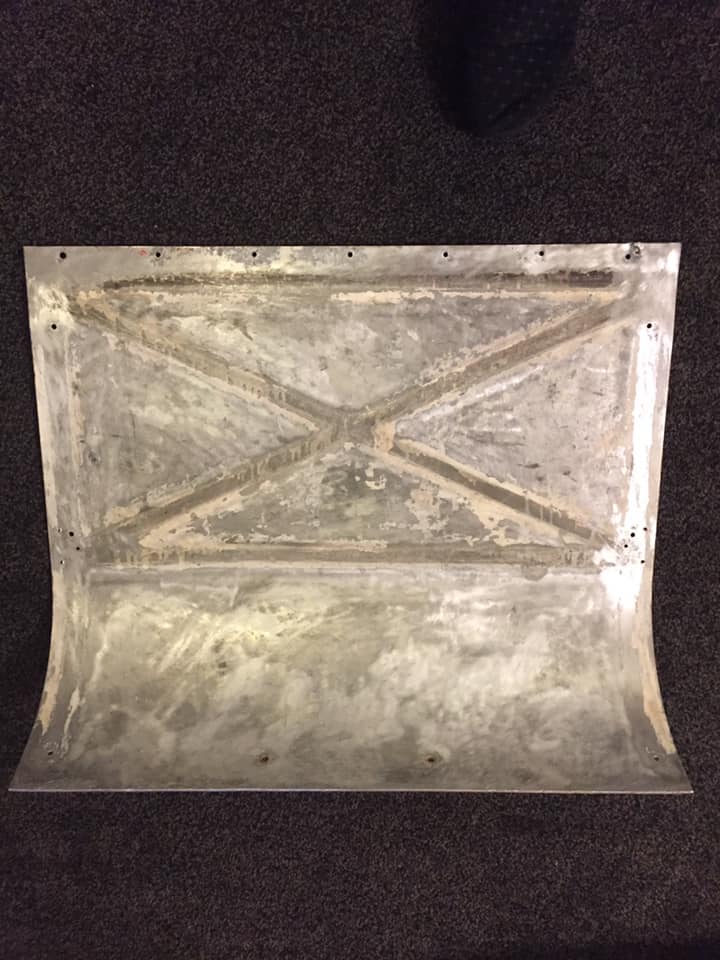

With 2018 well underway, the first small working party gathered at Romford to accommodate the fitting of a complete set of 6 new tyres. This was decided following the unfortunate incident on the day of the relocation to Romford when the appliance suffered a blow out on the motorway, fortunately, the driver was able to control the vehicle and continue the journey. During the day, a couple other small jobs were undertaken including finally resolving where the last few remaining diamond plate panels should be fitted!. these plates were usually hidden when the appliance was constructed so it is like a game of "Cluedo" trying to establish exactly where they go,but eventually it all made sense and they can now be returned to their correct locations. The first of the show dates has now been pencilled in and more will follow once the various groups around the country start to announce their shows. we look forward to announcing our attendance at some of these in due course, however, before we do venture out, more work will take place to bring the appliance to an even better position for showing, one of those jobs, the repainting of the interior of the cab, should start as soon as the weather improves enough for the paint to dry! Its surprising how much can be accomplished by just 2 people who are very determined and actually know what they are doing! So on the 1st November, Colin & Trevor met at Wicken and made more significant progress in the run up to the move to Romford.

The blue lights and front grill repeater all now work and flash correctly, this just leaves the fitting of a small switch for this work to be completed. The final fitting of the nearside front wheel was completed and the checker plate returned to its original position. The rotten offside inner wing sections were cut out and new sections welded in, this just leaves the hole behind the drivers pedals to trim up, rust treat and plate over and the new outer wing and wheel arch to fit. Once this is done, the second phase of the cab interior redecoration can be undertaken and the fittings can start to be reintroduced. |