|

A working party of 5 today, so quite a lot was acomplished.

Work continued in the cab on getting the last of the painting prep done and, towards the end of the day, 90% of the undercoat had been applied to the interior of the cab roof and back cab rear pane,and, as the weather was so nice,the rear locker was also prepped and undercoated. A significant moment occurred when 240FLM had the missing hand bell refixed, much fun followed while everyone tried to ring a tune. A working blue beacon light unit on the roof has been installed and just needs connecting now. A trial fit of the locker doors was made but it became apparent that a little bit of fettling is needed to get them to fit properly. The last bodywork fittings and steps were fitted and also the access cover plate on the turntable. Colin got on with finishing the fitting on the nearside inner arch and then, with help, also managed to fit one of the new front wheel arches which was bolted into place. Some of the bolts will have to be changed, but the wheel arch is in place. The "defective" pawl was removed and the problem of it sticking has been identified as worn pin so the required tension is not on the spring that pulls the pawl back into the housing. This is nowin the process of being remade ready to install next time. Pete & Colin got stuck into revealing the extent of the rot in the old inner front wheel arches, It was a little bit of a shock to see just how bad they were to say the least. Fortunately, Colin had come prepared with sheet steel and welder so after much cutting, sanding, cleaning and setting up, the first small panels on the nearside wheel arch were " tacked in". Pete got on with opening up the offside arch and also continued with the prep work on the cab interior. It was during that prep that Pete uncovered, very slowly, a remnant of the days when 240FLM was stationed at K22 Wandsworth

(1969-1981) when he discovered that someone had painted the appliance call sign, K223, on the dashboard! It had later been painted over during one of the 2 resprays the appliance has undergone. This will be cleaned and retained as it is an integral part of the appliance history. A significant step forward so far this month with the commencement of the re cabling of the ladders. The new cables had been sitting patiently for almost 2 years, and last week, Colin took the plunge and single handedly started the refit. A daunting task considering it has been over 2 years since he last saw a TL up close with all its cables attached! After an awful lot of effort, all the cable were finally attached and the scene was set for today Wednesday 11th October when Colin was going to have support form other group members with the final push. At the end of today, the cables had finally been rove correctly, secured at all points following the manufacture of new pulley pins and then finally turned around the pulley wheel block within the fulcrum ready for a test. Success!

3 working parties have taken place during the month, not to well attended unfortunately,but good and steady progress is still being maintained. The focus this month has been 2 fold, the reinstatement of the ladder fittings to enable the re-cabling to take place, and, the start of the cab interior refurbishment. Pete Weight has taken on the cab and Colin continues to progress the ladder fittings as well as the many other items he is either making or restoring. The ladder fittings, beautifully restored by Graham Pearce, have started to find their way back home and the cab has had a strip out of the old unwanted or inappropriate, later addition wiring and some original installations that look decidedly unsafe!

The paintwork has had a first rub down and both the front floor pans have been stripped back to reveal the condition of the floors. The OIC side, generally in very good condition and solid, required the insertion of a steel plate, suitably sealed with marine grade sealant, while the drivers side has revealed a rather unpleasant hole which will require a rotten section being cut out and plate being welded in. Other niggly jobs included drilling out broken screws and bolts followed by retapping to accept new units. Another section of nasty rust penetration has been discovered on the nearside lower corner of the windscreen mount, this can be back plated and filled in preparation for painting. The radio mount in the front of the roof has been prepared to receive the original radio pack which is now cleaned and ready to be installed once the painting is completed. Several items have been removed for restoration, these include the glove box, OIC seat frame, grab handles and the 2 original interior roof lights. Colin and Paul Wing formed the working party and between them they managed to get a few more jobs completed.

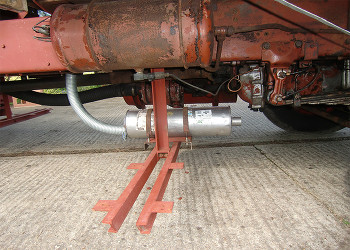

The sparge (Monitor fixed supply ladder mounted pipe) is now refitted to the ladder and Paul has done stirling work cutting the catches for the inspection panels on the deck and around the water pump.. Colin managed to refit the foot locker, interior end panels that allow access to the front pair of jacks. Unfortunately, we are 4 catches missing so new ones will need to be sourced. Colin Farrington, Trevor Barnwell and Steve Houston set about removing the rear wheels and the installation of the new rear wheel arches. A heavy task but after a long day they finally sat proudly on 240FLM.

Fitted at the same time were the new rubber trims which act as spacers and also protection to the metal contact points around the perimeter of the arch. Unfortunately, the top section of the wheel arches do not sit snug to the upper side panels so these will need to be remade during the winter. It appears that the new wing shape is a little shallower than the originals but unfortunately we had not spotted this. Still, all in all a significant step forward. Colin & Pete Weight met at Gressenhall to restart the years work, They managed to refit some of the beautifully restored" Kick down platforms for the No2 to stand on at the head of the ladder,a couple of the ladder pawls and the hook ladder brackets.

Colin installed for a trial fit the monitor and head roller mechanisms which he had been working on over the winter. A short but successful day and one which allowed us to see 240FLM moving so much closer to completion. She did look smart with her nose on! Although there was only me in attendance, it was a useful working day at Wicken yesterday.

managed to get all the remaining body panels fully polished out as well as 95% of the turntable. IN general, apart from quite a few small areas of rust/bubbling paintwork, the body work is in really good condition. I also had a go at cleaning one of the rear cab 1/4 lights that had fogged up and was pretty scratched. After a lot of research, I plumped for some of the Maguires PlastRX and a supersoft buffing head for the electric polisher donated by Mitch Theobold that I had been using on the body. Well, after 2 passes on the inside and 3 on the outside, I think we can strike off the need to replace the windows! I also had a single pass on one of the rear windows and again, brilliant results. All in all a good day. In the new year, I need to pick up a drill size polishing mop and then I can complete the polishing around the operators consul and the more intricate parts around the frame. Trevor Barnwell, Paul Wing and myself assembled at Wicken for a working party today. We straightened up the O/S of the pump housing and fitted all the alloy sheets and trim. I cut a new housing cover and refitted the "skin" while Trevor and Paul experimented on cleaning up the alloy decking.

We ran short of screws so although many parts were refitted some items will need the remainder of the screws fitting. Trevor had the covers off the console and checked all the electrics and repaired the blown fuses. Parts were taken away to be sourced/ replaced. Today, the working party was well attended and further progress was made as follows:

The last of the trim around the deck was fixed and the rear light wiring was completed.The framework around the pump was completed. The pump bay metalwork was reattached and, the rear panels and rear locker door were screwed back on. While these tasks were being completed other members washed the cab and bodywork and got the polishing machine to work on the paint work, the results were stunning and the paint is now looking good and the appliance has a "cared for" look again. Steve Houston, Paul Wing & Colin Farrington in attendance:

While Steve got on with continuing to fix the decking down, Paul started working on the lockers, treating the wood with knotting, bolting the lockers to the chassis, and getting 2 coats of paint on the internal surfaces. Colin had picked up the (hopefully) last of the wood we need on the way there so he cut out and shaped the wood to finish the pump housing which just needs the final bolting together next time once the bbitumen paint is dry. Colin Farrington & Trevor Barnwell in attendance:

Trevor started reinstating the rear wiring to the back lights and Colin fixed the deck plates in place at the rear, then, rebolting the outrigger that holds the O/S locker was completed and the front deck board was trimmed and 1st coated with paint. Trevor then stripped down the rear number plate holder; unfortunately, it is too badly rusted to use. So we discussed a solution which Trevor will try to get made. A working party of Steve Houston (with his daughter Joanna) Paul Wing, Pete Weight & Colin Farrington carried on with fitting and fettling the parts. Pete got another coat of paint on the wings while the rest of us fitted the O/S pump housing. We then fitted the deck boards around the turntable.

We then tried test fitting of the alloy deck plates and the rear bodywork but they will need screwing down on the next visit as we ran out of screws unfortunately! There are now only 4 pieces of wood to be cut and shaped to finish the pump housing off, which hopefully can be completed and everything screwed back on in the next 2 visits this month. November will see us refitting all the small items and catch fittings and looking towards re cabling the ladder. Paul Wood, Pete Weight & Colin were the working party today with most of the other regulars either on holiday, at work, or unwell.

While Colin fitted the N/S pump housing Paul and Pete carried on with rubbing down the wings. We then did a test fit of the N/S wings before Pete started to put colour on them. We took the O/S locker off to try and straighten the front mountings, this is not going to happen without some serious heat so I unbolted the hanger, this can be jacked back into place and the holes "adjusted" to make everything fit. The front "skin" was replaced and the front checkerplate fitted and the locker lifted back into place. The mountings for the O/S pump housing were drilled and fitted, so this is ready for the "skin" to be fitted and then can be attached. While this was going on Pete got the first coat of red on the wings, this needs to harden for at least 24 hours before being cut back and the next coat applied. I will sort out next working party dates later this week...... as they say "watch this space". A milestone in the restoration process was reached today!. With all the ladder extensions now painted, it was time to return them to the main ladder which is still attached to the turntable. A local car recovery agent was hired and arrived dead on time on a rather grey day.Most of us had thought this was going to be quite traumatic, however, the 2 guys who came with the HIAB lorry simply looked at the task and got stuck straight in. 20 minutes later, the ladders were reunited and 240FLM was once again looking pretty with her top hat on. The day continued with Steve Houston, Paul Wing, Pete Weight and Colin cracking on with the new wings and cleaning many of the small panels which were then refitted to the chassis.

A significant moment in the restoration process was reached.!A small group consisting of Colin, Trevor, Graham, Steve Houston and Pete Cowland managed to re-install the ladder sections into a single unit ready for the big lift which will finally see them reunited with the main ladder on 240FLM. Trevor managed to get all the new treads cut and fitted and the whole assembley looks brilliant.The missed areas of the ladders were painted at the same time.The front o/s locker is now made and part of the outside painted, next visit will see the skin back on and the painting finished and on the appliance. The decking is on the front n/s locker and finally, she is parked up in her "bay" again.

I Spent the day at Wicken with Trevor, we dodged the rain and got the ladder up and propped against the shed so that we could remove the ram and fit a new gaiter. After a bit of brute force we succeeded in removing the top mounting fitted the gaiter and started refixing the mount, after a couple of false starts we finally worked out the correct order for reassembly

The next problem was depressing the ladder, since it was near maximum elevation and very little weight on it we found that it did not want to depress! Attaching a ratchet strap encouraged it to return to the horizontal. I then started work on the front O/S locker and have cut out the front and work can continue on Sunday The working party was booked so I turned up! I was on my own so I am now talking to myself!

I searched round for all the bits of wood that made up the decking support around the turntable, I ended up with one piece missing, but as it was a mirror of the support on the other side it wasn't drastic. I have cut and sealed the underside of the rear deck support and made the pieces that go around the turntable. I have left the two rear ones long so that can be cut to length to fit exactly.These will be fitted on the next work party and the rear deck plates can the be fitted, along with the rear body work and trim: Dave has now welded the 3 prepared rounds into the ladder and repaired the jack control mounting and welded a new plate on the rear chassis.While he was doing this I made the frame for the deck plates, drilled and bolted this in place, found most of the angle plates that attach the sides and fitted these to the ends of the timbers.I then cut the ply that fits in front of these that the frame around the pump is attached to.So at long last parts are being attached again!

The first working party of July saw the re assembly begin!

There will need to be a bit of "adjusting " on the parts as we found that some of the mounting points had been bent over the years but nothing that can't be managed. We had a look at the gaiters on the rams and freed some of the fixings, then decided that actually installing the new gaiters is a job for another day. The top 2 ladder sections are now completely painted (maybe a bit of snagging) so we need to get the main ladder and first extension finished so the ladder can go back together. June 6th. Steve, Pete Cowland, Paul Wing and Colin assembled on the day and while Colin carried on with the construction of the nearside locker, Paul and Steve clambered over the main ladder section and started rubbing it down and managed to get a coat of paint on most of the areas tackled. Meanwhile, Pete carried on working on one of the other sections and completed the underside so that it is ready to be turned over for the other parts to be cleaned and painted. The locker is almost ready to be lifted onto the appliance to check the fit, it will then need painting and the alloy skin refitting and then it can be bolted on to the appliance. June 23rd: Another successful day! while the others got on with rubbing and painting the ladders I carried on building the near side locker.It is ready to be lifted onto the appliance and the finished length marked and the last two panels made. It can then be painted and the alloy skin refitted and it can be fitted back on the appliance.

A rather unpleasant wet day but more rubbing down and additional prep on the ladder sections and some paint added before the rain stopped the work.Colin & Trevor made excellent progress on finishing the rear locker, finally getting the all important coat of bituminous paint on it before offering it into place. It fits!

The new year has got off to a steady start with good progress being made, however, more hands are urgently needed to get 240 FLM to a state where she can be driven to her new, but yet to be found, home. 2 working parties attended by Colin Farrington, Steve Houston, Trevor Barnwell & Pete Weight, supported as ever by Lady Julia & Peter Russell saw continued work on the red oxide painting of the chassis, which is now about 95% done as far as we can without a pit- further work was done on wire brushing down the ladder sections and applying the hammerite. Bank holiday Monday and a site visit was made by Dave Porter (the welder) to measure and check on exactly what materials are needed to repair the 3 damaged rounds. repair the broken hydraulic lever bracket and weld on a new plate over the rotten rear section. Meanwhile, both Colin & Graham Pearce have been busy away from Wicken: Colin has begun making new box sections for the nearside lockers and Graham has constructed a home based sandblasting cabinet and has been putting the first of the small parts through it with excellent results. Another day of sunshine here, and wind died away altogether. Bit on the cold side though. Stalwarts appeared in persons of Peter Cowland, Peter Weight, Garry Warren and supervised by Colin Farrington. They got house ladder up to remove remains of the plastic sheeting, and covered the TL with it, to keep worst of rain ingress off the old lady. No, not Julia. 240 FLM that is. Hope it will stay put in forthcoming winter months. More rubbing down and painting done as well. Tools away until next year, unless something comes along that has to be dealt with. Well done gang, for turning up and getting stuck in.

|