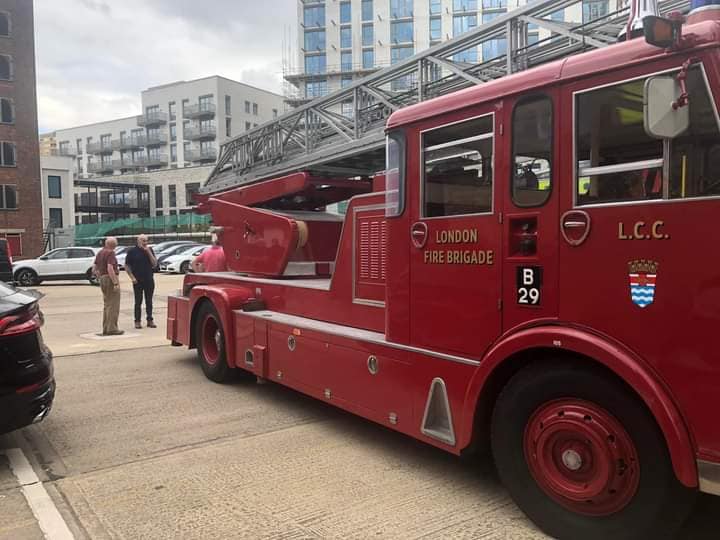

On Monday 15th July, we were privileged to be able to carry a well known and respected Fire Service enthusiast and dedicated LFB supporter, Ken Raven on his final journey through South London Ken had never been a member of the London Fire Brigade formally but dedicated his life to supporting the staff at many stations, particularly his beloved, local station at Deptford in South London. A true character, known throughout the Fire Service preservation and memorabilia circles, he was always keen to support as many charitable events as he could in support of UK Firefighters both locally and more widely. As the cortege passed E36 Deptford Fire Station, the duty personnel, complete with appliance, paraded on the forecourt as a sign of respect. Ken had spent many years in the station and had become “adopted” by the staff and would sometimes be found in attendance at incidents locally! We wonder how he got there!! On passing over Blackheath Common en route to the service at Eltham, an appliance was spotted coming towards the cortege, the Pump from Brixton Fire Station was heading to an emergency call and it was a fitting moment for Ken to have an appliance pass him on a “shout” ! Making its way along Eltham High Street, the public bore witness to the size and scale of the cortege which by now contained both 240FLM and the Pump from Deptford which had joined us. This was a fitting and deserved tribute to a much loved member of the Fire Service Preservation fraternity and supporter of the London Fire Brigade to which he had dedicated most of his life. Please note that all the images used here are copyright to Paul Wood - no unauthorised reproduction is permitted without express permission.  On Friday 12th July 2024. The group were proud to have been asked to escort former London Fire Brigade member, Chris Randell on his final shout in Billericay, Essex. Chris had joined the London Fire Brigade in 1968 and his firefighting career started at Shoreditch Fire Station. He worked his way through the junior ranks serving at Barking at Ilford. Chris finally departed the LFB after 10 years to work within the Fire Safety teams in the Oil Industry specialising in the high risk procedures of fighting fires involving Oils and associated liquids. You are courteously reminded that any images used to illustrate this article are subject to UK Copyright laws and no unauthorised reproduction is permitted. The funeral of the late, Divisonal Officer John Gayner (rtd) Essex County Fire & rescue Service.19/6/2024

In support of our fire service colleagues in the Essex Fire & Rescue Service, on the 19th June 2024, 240FLM was proud to have been asked to step in and carry the late, Divisional Officer John Gaynor (Rtd) from Essex Fire and Rescue Service, on his last shout.

We attended Leigh on Sea fire station to collect John and then made our way to the family home. With the full cortege assembled, the procession made its way gently around the town passing Johns sailing club before arriving for the final service at Basildon Crematorium. NB: In normal circumstances, the preserved AEC Merryweather based at the Essex Fire & Rescue Museum would have undertaken transporting John on this sad day, however, mechanical repairs that are currently underway prevented them from being able to fulfil the duty, hence 240FLM was proud to be able to step up at short notice. Please note: the images used here are copyright to Dave Porter and no unauthorised copying or reproduction is permitted.  On the 28th May 2024, the group were proud to have been approached to form a key part of the attendance to carry London Firefighter Albert Folivi on his final shout. In attendance for this incredibly sad and moving service for Firefighter Folivi were a number of London Fire Brigade Senior Officers, including the Brigade Deputy Commissioner, Charlie Pugsley, his colleagues from A31 Holloway Red Watch, a full parade of Brigade operational personnel, family and friends. Following the service which was conducted at St Marks Church, St Mark's Rise, Dalston, E8, Firefighter Folivi was carried in the traditional way on the deck of a Turntable ladder to the City Of London Crematorium at Wanstead. East London. Please note that the images used are copyright to the London Fire Brigade, Paul Wood and Dave Porter, No unauthorised copying or reproduction is permitted.  On Saturday 25th May, we were delighted to be able to take 240FLM down to the seaside at Whitstable in Kent to participate at the marriage of London Firefighter, Steve Hartingen to his beautiful bride Lou . The appliance, fully dressed for the day, shone as bright as the bride in the lovely sunny weather. With the appliance being parked on the green outside the Marine Hotel on Marine Parade overlooking the sea, it was joined by the appliance from the local fire station in Whitstable whose crew turned out smartly and really complemented what was a wonderful day for the bride and groom. Following the ceremony and photos, the bride and groom were driven around the town in the TL on a mini sightseeing trip. The images used to illustrate this artice are copyright protected to Dave Porter and Peter Cowland and no unauthorised reproduction is permitted. On Saturday 18th May 2024, and following an invitation, 240FLM wound its way through the streets of North London to support the community hub open day at “ The Old Fire Station” located in Leswin Road N16.

The centre contains a number of community based groups which include a childrens theatre, migrant advice centre, and sustainable food resource group amonst others. Before becoming a community hub, the fire station, built for the Metropolitan Fire Brigade in 1885 and subsequently adopted by the London County Council and thus the London Fire Brigade In 1902, was in operational use until the new fire station was built in 1975 at Stoke Newington Church Street. N16. The images used to illustrate this item are copyright to the individual photographers, Dave Porter & Paul Wing. No unauthrised reproduction is permitted. On Friday 26th April 2024, the 240FLM team were sad, but honoured to carry the late, retired, Station Officer Tony Thornes LFB, on his last shout.

On a beautiful sunny day, a huge turnout of family, friends, former colleagues and serving firefighters, complete with appliances from G27 North Kensington, Tony's last station, made their way with a host of senior officers to Amersham, Buckinghamshire for the service and cremation. Tony had passed away on 14th March 2024, a tremendously sad moment as he had been regarded by his peers as being one of the finest operational officers to work with and a truly nice man. It is rare to go through an entire service career and retire with a legacy such as his. It takes a particular character and personality to be respected and admired by all and Tony was one such person. Many of us in the group knew Tony personally as he had served in both the old D & G divisions in the LFB, and, those of us that did, now mourn the passing of an outstanding firefighter, father, husband and gentleman. Our thanks go to Ivan Barefield, Malcolm Burden, Pete Weight, Dave Porter & Tim Hoy for the use of their images and you are courteously reminded that no unauthorised reproduction or use is permitted. The 240FLM team were once again proud to have been asked to carry the late, Divisonal Officer, Christopher Evans on his last shout on Thursday 7th March 2024 to the South Essex crematorium, Upminster, Essex. A significant turnout of former colleagues from the LFB were in attendance to meet the family and express their fond and proud memories of a well liked and highly respected officer and gentleman. Chris had started his career at East Ham fire station and, following a series of promotions, was based at Barnet, Holloway and Plaistow before arriving as Station officer in the C division based at the former C22 Kingsland Road fire station, which is now sadly closed. Further promotions followed and he rose to the rank of Divisonal Officer. Please note that the images used are copyright to a number of photographers including Paul Wood, Len Sims, Alan Field and the FSC Moreton In Marsh. No unauthorised copying or reproduction is permitted.  On Wednesday 14th February 2024, a crew of five set off from Romford heading for Basingstoke in Hampshire in preparation to carry our dear colleague, and founder member, John Cox, on his final shout the following day. John was a proud, founder member of the 240 Preservation Group having driven, operated and ridden in the back of the appliance after it was transferred into to K22 Wandsworth in 1969 after its first 5 years of service at B29 New Cross. Born in Walworth, south London in 1947 John grew up in Streatham. In March 1967 he walked through the arch at the LFB training school at Southwark to begin recruit training. On passing out from training school he was posted to the red watch at K30 New Malden. In 1971 he transferred to the white watch at K22 Wandsworth where he first became acquainted with 240FLM. In the 1980s John moved to Basingstoke and in 1988 transferred to D26 Twickenham on the red watch. John retired from the LFB in 1995. Notable amongs John's adventures with 240FLM was the attendance and firefighting operations during the Iranian Embassy Siege which took place on the 5th May 1980. The Embassy, located in Princes gate, Kensington, West London was the subject of a terrorist incursion and hostage situation which ultimately required the SAS to intervene to end. John had been ordered, with his Officer in charge, to drive 240FLM from its base in Wandsworth to Kensington fire station to "cover" whilst the Kensington Turntable Ladder was in attendance at the incident. However, En route to Kensington, the SAS stormed the building resulting in a serious fire breaking out and thus requiring more fire brigade resources. 240FLM, with John at the wheel, were ordered straight to the fire and over the next few hours got to work as a "water tower" directing water into the upper floors and roof of the now blazing building. This was but one of the many incidents that John and 240FLM were jointly involved in during his long career. On ther day of the funeral, Basingstoke fire station (Hampshire Fire Brigade) gratefully provided overnight security for the appliance whilst the generosity of Johns family meant the crew were guests at a local hotel. The crews at Basingstoke also provided a guard of honour as his cortege passed by the station which was a moving and emotional moment. The funeral took place at Basingstoke crematorium where family and past colleagues gathered to witness John being carried on his ultimate journey by his beloved turntable ladders – better known to many as `Kilo two-two-three`. In November 2014, shortly after the group purchased the appliance from the Ebay auction site, John came face to face with it again in Wicken, Cambridgeshire where it was being stored prior to restoration. John generously arranged for his wife Carol to completely restore the original seats including upholstery at no cost to the group. A generous gesture indeed. Goodbye John, it was a pleasure old buddy. Photos used to illustrate this article have been generously provided by Dave Porter, Ivan Barefield, Pete Weight and The Cox family., UK Copyright rules apply. The first group "get together" at F38 Romford took place on the 9th January. On the menu for this working party was a thorough clean on the inside and outside and all the routine basic checks required for a vintage vehicle including tyre pressures, oil etc. A more specific job was tghe inspection and test of the appliance pump starter motor which had shown signs of "misbehaving".

Photos are copyright and courtesy of Dave Porter & Pete Cowland. The 240 FLM Preservation Group were proud to have been invited to carry the late, William “Bill Williams, former London Fire Brigade D.A.C.O (Deputy Assistant Chief Officer) on his final shout.

Bill had seen service with the 3rd Battalion, The Parachute Regiment during World War 2 and had been one of the thousands of paratroopers who had jumped into action during the ill fated operation, “Market Garden” at Arnhem in Holland in late 1944. He was captured during that fierce battle and spent the remainder of the war as a Prisoner. Following his war service and subsequent repatriation, in 1954, Bill started his LFB career and on completion of his training was posted to Plumstead fire station. His subsequent career saw him rise through the ranks, including spending time as an instructor to the newly created Junior Fireman scheme, before arriving in the Brigade, H Division as a Divisional Officer. Following this, his last posting was to the Brigade HQ at Lambeth where he remained for the remainder of his service. In 1985 Bill was awarded the Queen’s Fire Service Medal for distinguished service in the New Year’s Honours List. The funeral, conducted at Eltham Crematorium SE London, was attended by a wonderful parade of serving and retired members of The Parachute Regiment as well as former Brigade colleagues, family and friends. The images used to illustrate this item are copyright to the individual photographers, Dave Porter & Paul Wing. No unauthrised reproduction is permitted. The sunny climes of south London was the destination for 240FLM on Saturday 7th October to attend the annual open day and festivities at H26 Addington.

Wonderful weather and the enthusiastic local visitors ensured a good day was had by all. On show was one of the Brigade 32metre Turntable Ladders, ambulances, police vehicles and other fun entertainments. Images courtesy of Dave Porter and the LFB. No reproduction is permitted without permissions. Copyright laws are applicable. For their annual "open day", A33 Tottenham Fire Station had their three appliances on show [Pump Ladder, Pump & Turntable ladder} and A346 - Edmontons Fire Rescue Unit (FRU) made an appearance. On the more unusual front, OK9 – the London Fire Brigade fire investigation dog Simba and his handler Anton Keach along with Simon from the London Fire Brigade Drone Team was also there with an array of drone equipment on show. Warm, sunny weather was above for most of the day and the ice cream van did a brisk trade. The on duty crews from A33 Tottenham crew put on a well-received drill which was a simulation of a building fire, with associated smoke, and people needing to be saved from the upper floors, using their 32 metre Turntable ladder and also a 135 ladder, the Mayor of Haringay also managed to be saved at one point.! Rare public access to the BA chamber was available and the kids (and some adults) could squirt some water. A display of historic incidents which the crews from Tottenham fire station have attended over the years attracted a lot of attention and the Firefighters Charity were in attendance and raffling some prizes, including a `Tottenham Hotspur experience`. All in all, another fun filled, but long day, which our crew thoroughly enjoyed. Our gratitudes are sent to the photographers, Dave Porter, Peter Murch and Paul Wood who have kindly provided the photographs which are all subject to the usual copyright laws (UK). No unauthorised reproduction is permitted without their express permission. The group were proud to have been invited to undertake the carriage of London Firefighter Danny Hunt O'Brien on his final “shout” on the 19th February 2023 to the City of London Crematorium and Cemetery. London E12

Firefighter Hunt had been attached to F22 Poplar Green Watch since he joined the Brigade in 2018. Several stations attended with their appliances and the Command senior officers were also in attendance to participate in the deserved honour guard for a very popular colleague. The funeral was supported by dozens of family and friends and 240FLM was able to utilise their newly hand built coffin transport deck which had just recently been completed by group members and close friends. You are respectfully reminded that the images used to illustrate this article are copyright protected to the photographers: Paul Wing and Dave Porter and no unauthorised reproduction is permitted. With her crew smartly dressed for the day, 240 FLM wound her way down to sunny Saffron Walden in Essex to collect the groom, Serving London Firefighter, Sub Officer Charlie Hasler and deliver him safely into the arms of his beautiful bride, Loren. Quendon Hall in Essex was their venue for their special day and beautiful weather was on tap to compliment the event Charlie is currently an operational Sub Officer at Hillingdon fire station and there were several other firefighters attending who knew some of our crew so some reminiscing took place! As ever, you are courteously reminded that images used to illustrate these articles are strictly copyright protected to the individual photographers and no unauthorised reproduction is permitted. On the 10th of September 240FLM went to the relatively local Lambourn car show in aid of local charities to line up alongside several very well restored American and English cars and motorbikes. A very hot day was enjoyed by everyone and made for some interesting conversations.

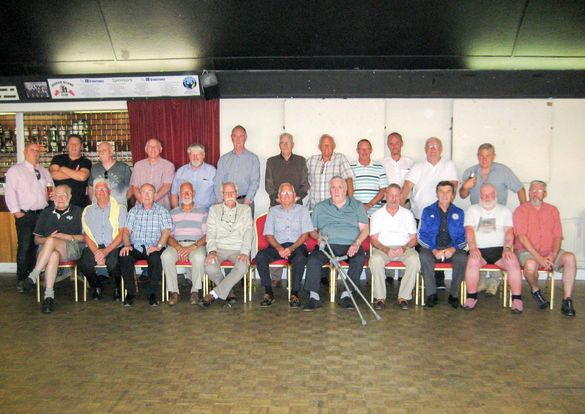

Images are not for reproduction and copyright protected to the individual photographers. Saturday 26th August saw another of the popular get togethers organised jointly by the LFB Retired Members Association (D and G Divs) and station staff for retired members of the LFB, and in particular, those formally based at the station. Another busy day for 240FLM and her dedicated team as they made their way around the North London zone this time to Southgate Fire station for their annual open day. |